|

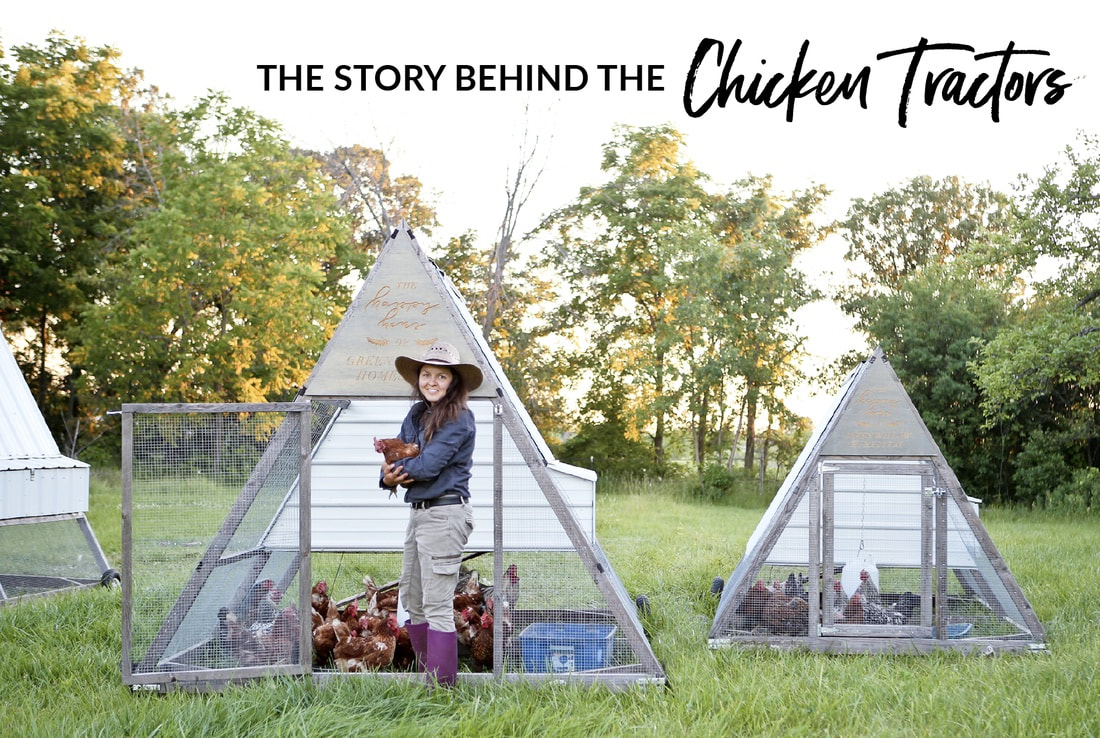

After years of dreaming, I finally had a flock of chickens to call my own. The most beautiful hens that laid eggs like crazy. I let them free-range because I knew it was best for their health and happiness.

I came out to check on my girls one afternoon and realized there were feathers everywhere. A handful of my hens were missing. A predator had been through our flock and I instantly felt guilty. I became all too familiar with this guilt-ridden anxiety. In my first year of owning chickens, I lost four hens and a rooster to a nasty hawk. No matter what anyone said to comfort me, I still felt it was my responsibility to keep them safe. I'm sure as a chicken momma or papa you've felt this way too. |

|

Chickens belong on pasture, out in the sunshine, and they deserve ample access to bugs. How was I supposed to protect my hens, but also give them the freedom of "free-range"?

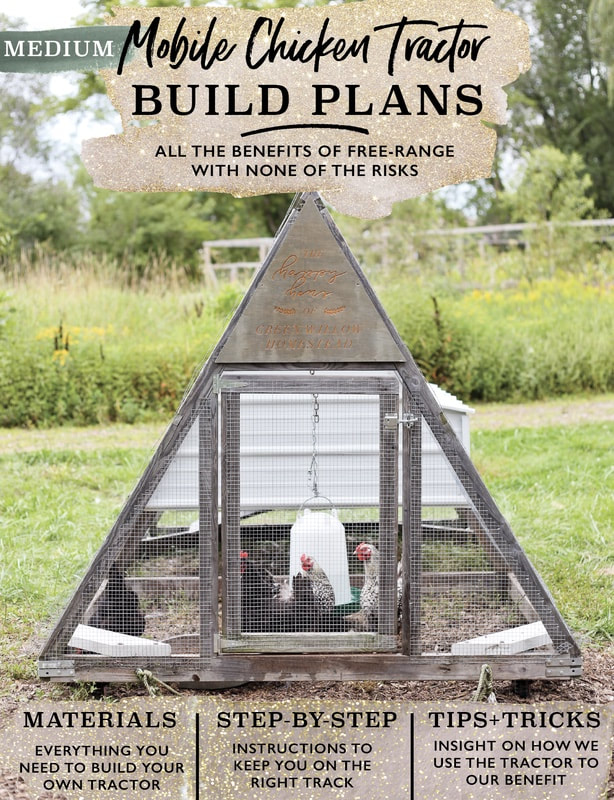

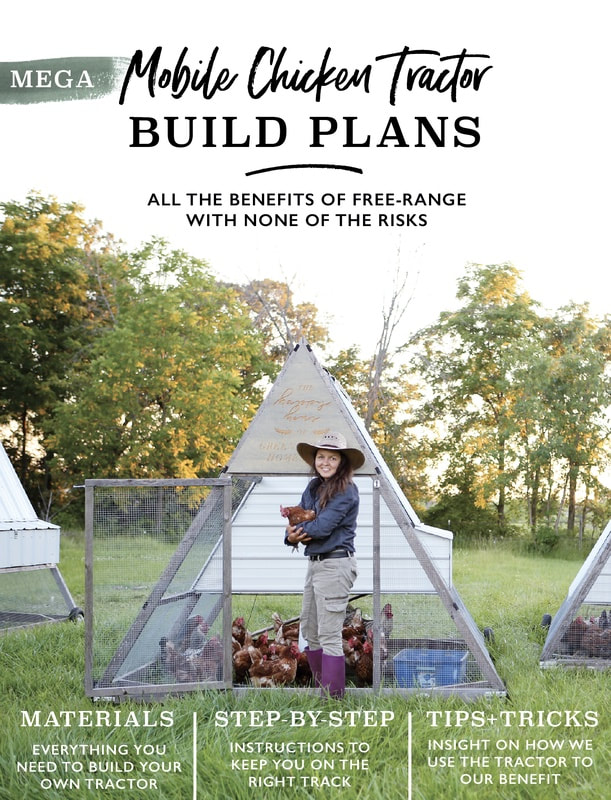

Here at Green Willow Homestead we knew we needed a structure that would keep our hens completely safe, but offered the flexibility for them to have access to pasture. So my husband and I went to work learning about all the different options and experimenting with different designs until we finally came up with a design we loved. Our hens have never been happier and safer. I want you to feel the same sense of security and relief I now feel as a chicken owner, so that's why we created the A-Frame Chicken Tractor Build Plans. |

THE A-FRAME CHICKEN TRACTOR PERKS

|

Predator pressure is a non-issue now that we house our flocks in these A-Frame Chicken Tractors. We live in a massive wildlife corridor and see everything from bald eagles to coyotes. Nevertheless, in seven years we have yet to lose a single hen inside our tractors.

Our ladies get to fulfill all their chicken needs by scratching through the grass and clover, searching for bugs and worms to eat. Their yolks are a deep orange and our farm's customers couldn't be more pleased. The A-frame chicken tractor has a unique wheel design that went through many versions until we found the one that would stand the test of time. We came up with this design all on our own and have yet to see another build plan online that utilizes it. As a 5'4" 135 lb female, I can move and turn these tractors on a dime, all by myself. Having a mobile structure to move across the grass that is both aesthetically beautiful and sturdy is a godsend. From the A-frame design to the solid-rubber tires, our tractors are made to last. We wanted to build it once and have it be maintenance free and last. |

|

Gathering eggs has been a breeze. We get about 5 dozen eggs a day and having exterior access to nesting boxes has been essential to our efficient workflow on the farm.

The chickens fertilize our pasture for us, creating a noticeable difference in the health of our land after just one month. White corrugated steel reflects the sun, which helps the hens stay cool during the day and then dry and warm if a storm rolls in. The roosting area gets shut up safe and tight with a ramp that operates on a special pulley system. The added bonus is this system allows you to move the tractor in the morning before you let them out without any hens getting in the way. The other added bonus is many cities have tight building codes and a mobile structure like the A-frame chicken tractors doesn't require a permit. Our city has a lot of red tape for building permanent structures so constructing a mobile tractor was the path of least resistance. |

THE A-FRAME CHICKEN TRACTOR BUILD PLANS

|

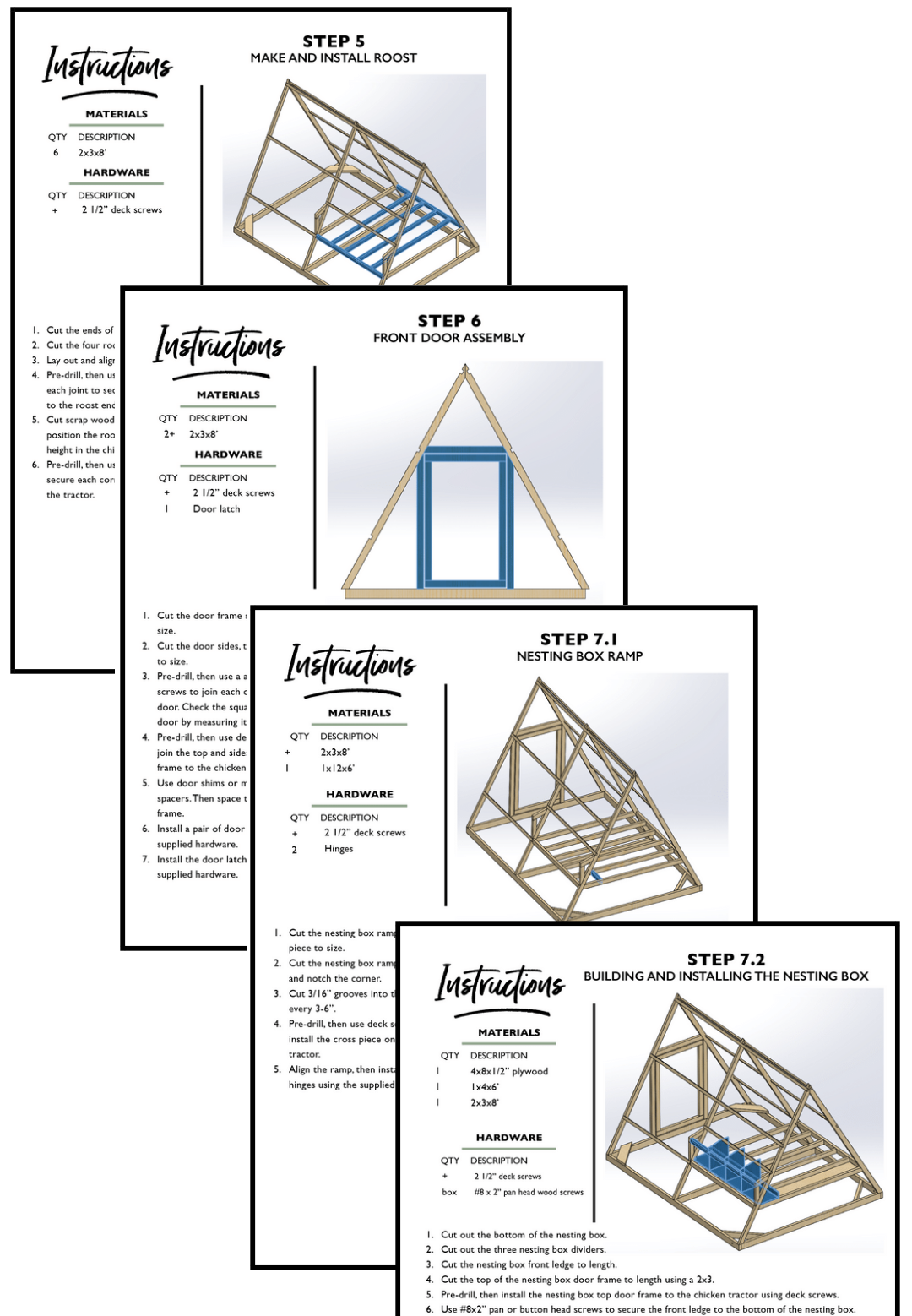

I spent four months researching what we needed in order to merge the benefits of free-range eggs with the necessity of safety from predators.

My engineering-inclined husband set to work on computer aided design (CAD) software and 3D modeled the entire design. One trip to Menards and an Amazon order later, we were on our way. The build plans are downloadable, printable, and come with all the information needed to get started:

We then batch-built three A-frame chicken tractors over the course of a month. A single tractor will take on average 20 - 24 hours of construction time based on skill level. While most of the tractor can be built solo, a second set of hands will definitely make a handful of steps much easier. |

CHECK OUT THIS AWESOME TIMELAPSE OF ONE OF OUR CUSTOMERS BUILDING THE TRACTOR!

BUILD YOUR OWN A-FRAME MOBILE CHICKEN TRACTOR

...

...

...

*If you are having issues opening the links to purchase or view the tractors, visit our digital store directly at this link*

FREQUENTLY ASKED QUESTIONS

Q: What tools do I need for building the chicken tractors?

A: Here is a list of the tools you will need to build the A-frame chicken tractor:

A: Here is a list of the tools you will need to build the A-frame chicken tractor:

- Circular or table saw

- Miter Saw

- Jig saw

- Drill

- Assorted drill bits

- Stapler - T50 or equivalent

- Tin snips

- Pliers

- Screwdrivers

- Assorted sockets

- Assorted wrenches

- Paint brush

- Square

- Tape measure

- Straight edge

- Pencil and Sharpie

Q: What skill level do I need to build the chicken tractor?

A: You need to have experience building something. This means you've used power tools, you know how to take measurements, and you can follow directions. The plans are exact, very detailed, and include in-depth diagrams to help you. First and foremost, we recommend reading through the plans from beginning to end to understand how all the steps fit together. Once you do this, then take it one step at a time. If you are unsure about a step, we recommend using cardboard first to map it out to be sure you've measured and cut correctly. Lastly, if you don't have experience building something and you've fallen in love with our build plans, ask someone who does have building experience to help you construct them.

A: You need to have experience building something. This means you've used power tools, you know how to take measurements, and you can follow directions. The plans are exact, very detailed, and include in-depth diagrams to help you. First and foremost, we recommend reading through the plans from beginning to end to understand how all the steps fit together. Once you do this, then take it one step at a time. If you are unsure about a step, we recommend using cardboard first to map it out to be sure you've measured and cut correctly. Lastly, if you don't have experience building something and you've fallen in love with our build plans, ask someone who does have building experience to help you construct them.

Q: In the photos we can see under some of the wood beams along the bottom. Do you not have small animals digging or squeezing under?

A: In five years, we have never had a single predator dig under the tractor. During the day predators are mainly aerial - i.e. hawks. Hawks cannot get to the birds in the tractors thanks to the galvanized metal 2x4” fencing we use. As for night time predators (like raccoons, mink, opossum, coyotes, and weasels), we've found that moving the tractor every day keeps predators on their toes. They can't make heads or tails of the situation when the tractor is in a different spot every night.

From there, the roosting area is accessed by the hens via a ramp. This ramp is on a pulley that you close at night and open back up in the morning.

For those who deal with egg-eating snakes, our customers have successfully retrofitted an additional strip of hardware cloth (1/4" or 1/2") underneath the bottom of the tractor to cover the additional 2-3" underneath. This addition slightly restricts the mobility of the tractor, however, our customers have not reported any major issues.

A: In five years, we have never had a single predator dig under the tractor. During the day predators are mainly aerial - i.e. hawks. Hawks cannot get to the birds in the tractors thanks to the galvanized metal 2x4” fencing we use. As for night time predators (like raccoons, mink, opossum, coyotes, and weasels), we've found that moving the tractor every day keeps predators on their toes. They can't make heads or tails of the situation when the tractor is in a different spot every night.

From there, the roosting area is accessed by the hens via a ramp. This ramp is on a pulley that you close at night and open back up in the morning.

For those who deal with egg-eating snakes, our customers have successfully retrofitted an additional strip of hardware cloth (1/4" or 1/2") underneath the bottom of the tractor to cover the additional 2-3" underneath. This addition slightly restricts the mobility of the tractor, however, our customers have not reported any major issues.

Q: At night, the chickens are tucked up in the enclosed, raised area - this has only a wire bottom, correct? So, if an animal got inside somehow, could it get through that wire under the roosts?

A: We use a 2x4” galvanized metal fence underneath the roosting bars. Any smaller, and their manure would not fall through to the ground at night. Raccoons would be the only issue, but as mentioned, when the tractor is moved every day we confused their ability to "stake out" how to infiltrate the coop. I can't stress enough how much of a wildlife corridor we are in here in Shell Lake, WI I and we have had zero predator issues with these tractors.

A: We use a 2x4” galvanized metal fence underneath the roosting bars. Any smaller, and their manure would not fall through to the ground at night. Raccoons would be the only issue, but as mentioned, when the tractor is moved every day we confused their ability to "stake out" how to infiltrate the coop. I can't stress enough how much of a wildlife corridor we are in here in Shell Lake, WI I and we have had zero predator issues with these tractors.

Q: What do you do with the chicken tractor in the winter? Do you move chickens to a stationary coop for colder months?

A: If your winters stay above 20°F then the tractor would be acceptable as year-round housing. Anything below 20°F and you would need to winterize the tractor. You have a few options for winterizing the tractor.

The first option is to keep the chicken tractor outside and make some adjustments to the materials used during the winter. The spot you set the tractor should be out of the wind with a good amount of sunlight throughout the day to keep it warm. First, add mylar reflective insulation to the interior of the white metal roof of the enclosed roosting area. Adhere it to the underside of the metal roosting area using double-sided foil tape. If you install our optional diagonal roosting bars, you can close off the roosting area from below with plywood as well and add a thick layer of straw or pine shavings. You can also consider installing a chicken heating mat along the sides of the roosting area for a safe source of extra warmth. All of these additions will keep the hens warm while roosting at night.

Then to protect hens from the elements when they are active during the day, we suggest using clear polycarbonate plastic sheets cut to size and zip tie them to the fencing to create a sort of greenhouse out of the tractor for your hens. Think wherever there is fencing on the tractor, you are adding polycarbonate over those spots (except under the roosting area). The hens must be kept out of the wind and snow to prevent frostbite. I suggest zip ties because then you can clip them off and take the polycarbonate sheets down during the summer and go back to the open-air fencing. You would add a thick layer of chopped straw to the ground inside the tractor as a boredom buster, insulation, and to absorb manure.

The second option is to park the entire tractor in a garage or barn for the winter, add straw to the tractor floor, and turn a light on for them during the day. We've been told this was beneficial for the chicken owner too in a garage-scenario because they don't have to go outside to feed their hens on the coldest days. The downside is you may have to give up a spot for a car during the winter.

With both options, you need to be sprinkling Sweet PDZ powder (organic) over their manure each day to keep ammonia smells down. This is always the biggest issue with any coop scenario during the winter. Much more manure in one spot without proper sanitization means more stinkiness for your birds. With garage scenario, you can roll the tractor out of the garage, sweep the used straw into a pile outside, then roll the tractor back in and add fresh straw. With the winterized tractor scenario, we recommend completely cleaning the straw out from under the roost. With both options, we recommend cleaning 2x per month and adding fresh straw. To learn more about the DIY mix we use you can read my blog post here.

A: If your winters stay above 20°F then the tractor would be acceptable as year-round housing. Anything below 20°F and you would need to winterize the tractor. You have a few options for winterizing the tractor.

The first option is to keep the chicken tractor outside and make some adjustments to the materials used during the winter. The spot you set the tractor should be out of the wind with a good amount of sunlight throughout the day to keep it warm. First, add mylar reflective insulation to the interior of the white metal roof of the enclosed roosting area. Adhere it to the underside of the metal roosting area using double-sided foil tape. If you install our optional diagonal roosting bars, you can close off the roosting area from below with plywood as well and add a thick layer of straw or pine shavings. You can also consider installing a chicken heating mat along the sides of the roosting area for a safe source of extra warmth. All of these additions will keep the hens warm while roosting at night.

Then to protect hens from the elements when they are active during the day, we suggest using clear polycarbonate plastic sheets cut to size and zip tie them to the fencing to create a sort of greenhouse out of the tractor for your hens. Think wherever there is fencing on the tractor, you are adding polycarbonate over those spots (except under the roosting area). The hens must be kept out of the wind and snow to prevent frostbite. I suggest zip ties because then you can clip them off and take the polycarbonate sheets down during the summer and go back to the open-air fencing. You would add a thick layer of chopped straw to the ground inside the tractor as a boredom buster, insulation, and to absorb manure.

The second option is to park the entire tractor in a garage or barn for the winter, add straw to the tractor floor, and turn a light on for them during the day. We've been told this was beneficial for the chicken owner too in a garage-scenario because they don't have to go outside to feed their hens on the coldest days. The downside is you may have to give up a spot for a car during the winter.

With both options, you need to be sprinkling Sweet PDZ powder (organic) over their manure each day to keep ammonia smells down. This is always the biggest issue with any coop scenario during the winter. Much more manure in one spot without proper sanitization means more stinkiness for your birds. With garage scenario, you can roll the tractor out of the garage, sweep the used straw into a pile outside, then roll the tractor back in and add fresh straw. With the winterized tractor scenario, we recommend completely cleaning the straw out from under the roost. With both options, we recommend cleaning 2x per month and adding fresh straw. To learn more about the DIY mix we use you can read my blog post here.

Q: Can you install an automatic coop door opener on the tractor?

A: Yes! Our customers have had the best luck with Chicken Guard Extreme due to the weight of the ramp and the need for the door to operate in colder weather.

The majority of our customers install the device on the inside of the roosting area (see the picture for reference) for ease of installation. This means that the light sensor isn't engaged as much as it would be if it were installed on the exterior. If you choose to install it on the exterior of the tractor, you can install metal pulleys to operate the pull wire internally.

What you do need to do is *reverse* the internal wire because they have their programming to be set up *opposite* of what you would need to open the ramp - i.e. opening the ramp on our tractors would actually require the "close function." Chicken Guard's customer service can walk you through this switch.

The ramp's weight is about 4.5lbs so you could modify our building specifications to make a lighter ramp as well and go with a smaller Chicken Guard model.

A: Yes! Our customers have had the best luck with Chicken Guard Extreme due to the weight of the ramp and the need for the door to operate in colder weather.

The majority of our customers install the device on the inside of the roosting area (see the picture for reference) for ease of installation. This means that the light sensor isn't engaged as much as it would be if it were installed on the exterior. If you choose to install it on the exterior of the tractor, you can install metal pulleys to operate the pull wire internally.

What you do need to do is *reverse* the internal wire because they have their programming to be set up *opposite* of what you would need to open the ramp - i.e. opening the ramp on our tractors would actually require the "close function." Chicken Guard's customer service can walk you through this switch.

The ramp's weight is about 4.5lbs so you could modify our building specifications to make a lighter ramp as well and go with a smaller Chicken Guard model.

Q: Can you move the tractor easily?

A: If you stick to the wheel design we provide in the build plans then yes, the tractor is extremely easy to move. We've found that some of our customers have cut corners at times and not followed our instructions on what wheels to use and they ultimately pay the price. While the tractors were designed with minimal weight in mind they are built to last, and our special wheel design keeps it mobile as well as durable. I am a 5’4” 135 lb female and I can move the tractors completely on my own.

A: If you stick to the wheel design we provide in the build plans then yes, the tractor is extremely easy to move. We've found that some of our customers have cut corners at times and not followed our instructions on what wheels to use and they ultimately pay the price. While the tractors were designed with minimal weight in mind they are built to last, and our special wheel design keeps it mobile as well as durable. I am a 5’4” 135 lb female and I can move the tractors completely on my own.

Q: Can I move the tractor with an ATV or garden tractor if I want?

A: Yes! We created a custom tow-bar for the Chicken Tractor so you can do just that with zero fuss. The tow bar features thick-walled steel tubing and precision laser-cut steel plates which easily bolt together. Both the tow bar mounts are mounted to the tractor using quick attach/detach cotterless hitch pins. This allows the tow bar to be installed or removed from your tractor in a matter of seconds. A long tongue on the tow bar allows garden tractors or ATVs to complete super-tight turns. It's a godsend if you plan on moving the tractor great distances - like down a dirt road or trail.

A: Yes! We created a custom tow-bar for the Chicken Tractor so you can do just that with zero fuss. The tow bar features thick-walled steel tubing and precision laser-cut steel plates which easily bolt together. Both the tow bar mounts are mounted to the tractor using quick attach/detach cotterless hitch pins. This allows the tow bar to be installed or removed from your tractor in a matter of seconds. A long tongue on the tow bar allows garden tractors or ATVs to complete super-tight turns. It's a godsend if you plan on moving the tractor great distances - like down a dirt road or trail.

HAPPY CUSTOMERS + HAPPY HENS

To date, over 6000 A-Frame Mobile Chicken Tractors have been built for happy and safe hens all over the world!

...

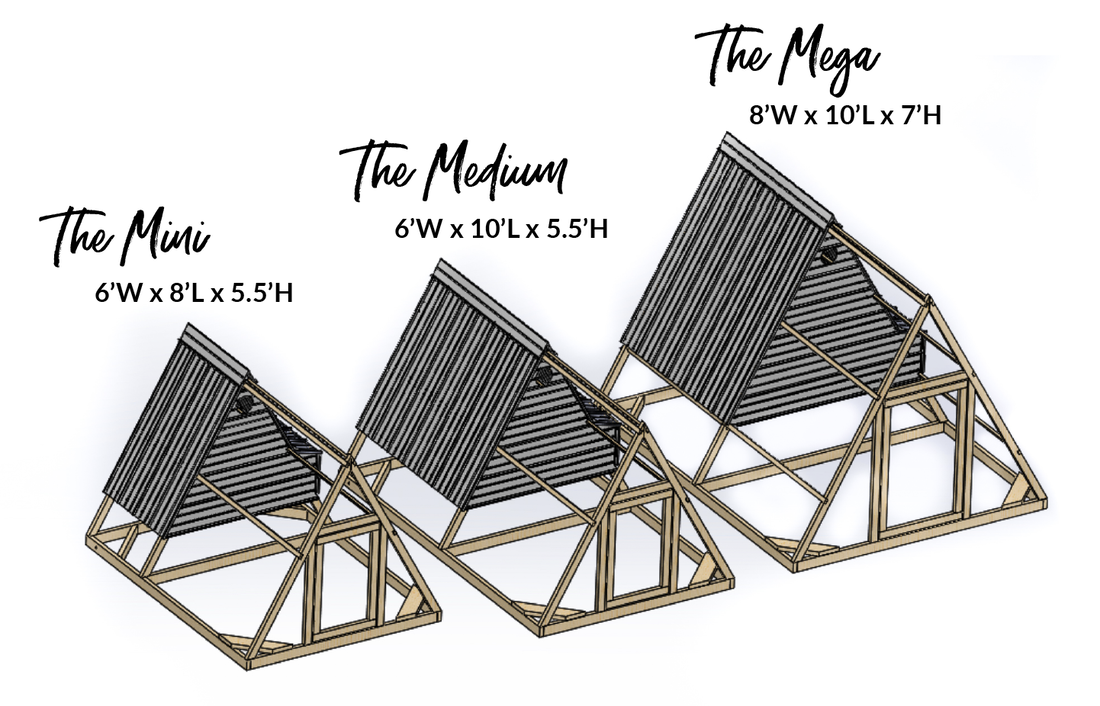

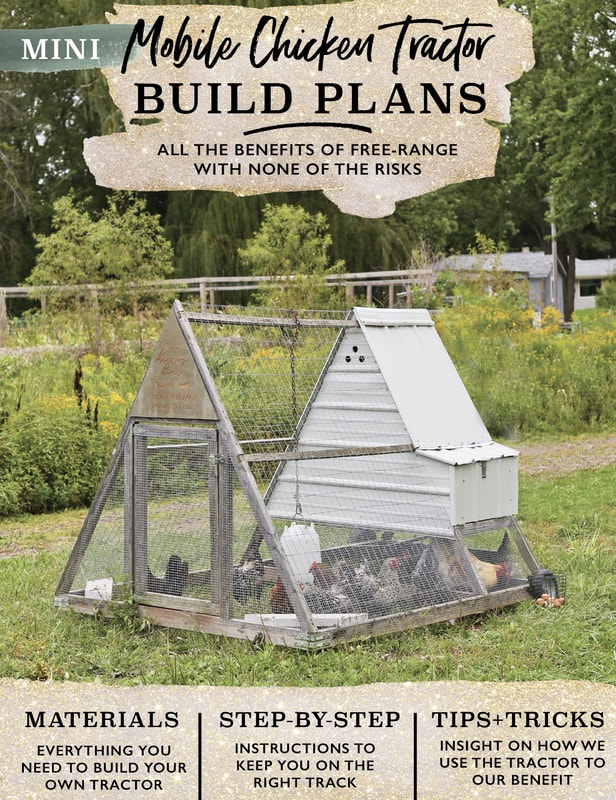

The Mini Mobile Chicken Tractor Build Plans45-page PDF includes full materials + hardware list, step-by-step instructions, and full color diagrams + pictures.

|

Got questions before you purchase the build plans?

|

FOLLOW KELSEY ON INSTAGRAM!

As an Amazon Associate I earn from qualifying purchases. |